Drone Inspections: How they are Revolutionising Data Acquisition

Drone Inspections: How they are Revolutionising Data Acquisition

As technology advances, companies are increasingly looking for more efficient, cost-effective, and safer methods for conducting asset inspections. Traditional inspection methods, which often involve manual labor, scaffolding, and significant downtime, are gradually being replaced by innovative solutions such as drones. Unmanned Aerial Systems (UAS), commonly known as drones, are emerging as a leading technology for asset inspections across various industries. Here’s why your company should consider using drones, the industries where they excel, and how UAS Imagery can provide you with an industry-leading solution.

Why Use Drones for Asset Inspections?

Why Use Drones for Asset Inspections?

Efficiency and Speed: Drones can significantly reduce the time required for inspections. Traditional methods often involve setting up scaffolding, shutting down operations, and putting workers at risk by having them perform inspections at height. Drones can access hard-to-reach areas quickly and easily, allowing for more inspections in less time and with minimal disruption to ongoing operations.

Cost-Effectiveness: The use of drones can substantially lower the costs associated with asset inspections. By eliminating the need for scaffolding, cranes, or helicopters, companies can save on both equipment and labor costs. Additionally, because drones can complete inspections faster, downtime for critical infrastructure can be minimized, further reducing costs.

Enhanced Safety: One of the most significant advantages of using drones is the enhanced safety they offer. Inspections of high-risk areas such as rooftops, bridges, and industrial plants traditionally require workers to operate in hazardous environments. Drones eliminate the need for workers to be exposed to these dangers, thereby reducing the risk of accidents and injuries.

High-Quality Data: Drones are equipped with advanced cameras and sensors that can capture high-resolution images, videos, and other types of data. This data can be analyzed to detect issues such as corrosion, structural damage, or equipment wear and tear with greater accuracy than the human eye can achieve.

Ideal Industries for Drone Inspections of Assets

Drones are versatile tools that can be used across a wide range of industries. Some of the sectors that are particularly well-suited for drone-based inspections include:

- Energy and Utilities: Power lines, wind turbines, and solar panels are assets that require regular inspections to ensure they are functioning correctly. Drones can quickly and safely inspect these assets without the need for shutdowns or putting workers at risk.

- Oil and Gas: Inspections of pipelines, flare stacks, and offshore rigs can be challenging due to the remote locations and hazardous conditions. Drones can access these areas easily and provide real-time data that helps in detecting leaks, corrosion, or other issues.

- Infrastructure: Bridges, tunnels, and roads are critical assets that require regular inspections to maintain safety and structural integrity. Drones canperform detailed inspections of these assets, including hard-to-reach areas that would be difficult or impossible to inspect using traditional methods.

- Telecommunications: Cell towers and communication infrastructure are often located in remote or difficult-to-access areas. Drones can provide a cost-effective and efficient solution for inspecting these assets, ensuring they are operating at peak efficiency.

- Agriculture: In the agricultural sector, drones can be used to inspect crops, monitor irrigation systems, and assess the health of large fields. This allows for more targeted and efficient use of resources, leading to increased productivity and reduced costs.

Assets That Can Be Inspected Using Drones

Drones are capable of inspecting a wide variety of assets, including:

- Power lines and transmission towers

- Wind turbines

- Solar panels

- Pipelines

- Bridges and tunnels

- Industrial chimneys and flare stacks

- Cell towers

- Railway lines

- Building rooftops

- Agricultural fields

Data Output Formats

Data Output Formats

The data collected by drones during inspections can be output in various formats, depending on the specific needs of the client. Common formats include:

High-Resolution Images: These images can be used for detailed visual inspections, allowing engineers to identify issues such as cracks, corrosion, or other forms of damage.

Videos: Real-time video feeds can be used for live inspections or recorded for later analysis.

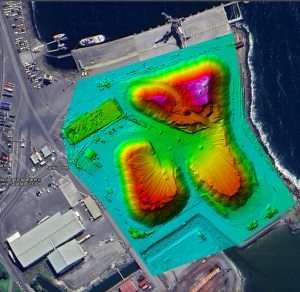

3D Models: Drones equipped with LiDAR or photogrammetry capabilities can create detailed 3D models of assets, providing a comprehensive view of their condition.

Thermal Imaging: Thermal cameras can detect heat signatures, making it possible to identify issues such as overheating equipment, electrical faults, or leaks.

Orthomosaic Maps: These maps are created by stitching together multiple images taken by the drone, providing a detailed and accurate representation of large areas.

Benefits of Drones Inspections

- Comprehensive Coverage: Drones can cover large areas quickly, providing a comprehensive view of the asset being inspected. This is particularly useful for assets spread over vast areas, such as pipelines or power lines.

- Real-Time Data Collection: Drones can transmit data in real-time, allowing for immediate analysis and decision-making. This is critical in situations where time is of the essence, such as during emergency inspections following a natural disaster.

- Repeatability: Drones can follow the same flight path on multiple occasions, allowing for consistent and repeatable inspections. This is important for monitoring changes in an asset’s condition over time.

- Detailed Analysis: The high-resolution data collected by drones can be analyzed in detail, providing insights that may not be possible through traditional inspection methods.

Types of Detection Capabilities

Drones can be equipped with a variety of sensors and cameras, allowing them to detect a wide range of issues, including:

- Visual Damage: High-resolution cameras can detect cracks, corrosion, and other forms of visible damage.

- Thermal Anomalies: Thermal cameras can detect heat signatures that indicate overheating equipment, electrical faults, or leaks.

- Gas Leaks: Specialized sensors can detect the presence of gases, allowing for the early detection of leaks in pipelines or industrial plants.

- Ultrasonic Testing: Drones equipped with ultrasonic sensors can detect structural weaknesses or internal defects in materials.

Safety Aspects of Drone Inspections

Using drones for asset inspections significantly enhances safety by reducing the need for human workers to access hazardous environments. Traditional inspections often require personnel to climb heights, navigate confined spaces, or work in proximity to dangerous machinery or chemicals. These conditions pose substantial risks, including falls, exposure to toxic substances, and accidents involving heavy equipment.

Drones eliminate these dangers by performing inspections remotely, allowing workers to remain in safe, controlled environments. Equipped with high-resolution cameras and sensors, drones can access hard-to-reach areas, such as tall structures or intricate pipelines, without putting human lives at risk. Moreover, the real-time data collected by drones enables quick decision-making, reducing the time spent in potentially hazardous situations. By minimizing the exposure of workers to dangerous conditions, drones represent a significant advancement in maintaining safety during asset inspections.

Laws Surrounding the Use of Drones for Asset Inspections

The use of drones for commercial purposes, including asset inspections, is regulated by various laws and regulations. In Australia, The Civil Aviation Safety Authority (CASA) governs drone operations. Key regulations include:

- Part 101: This regulation covers the operation of small unmanned aircraft systems (UAS) and includes requirements such as maintaining visual line of sight, not flying over people, and not exceeding an altitude of 400 feet.

- Waivers and Authorisations: In some cases, companies may need to obtain waivers or authorisations to operate drones in certain areas or under specific conditions that fall outside the standard Part 101 regulations.

For more information on FAA regulations, you can visit the FAA’s official website.

How UAS Imagery Provides an Industry-Leading Solution

At UAS Imagery, we specialise in providing cutting-edge drone-based asset inspection solutions that are tailored to meet the unique needs of our clients. Our team of experienced drone operators and data analysts work closely with you to ensure that your inspections are conducted safely, efficiently, and with the highest level of accuracy.

We utilise the latest drone technology, equipped with advanced sensors and cameras, to capture high-quality data that can be analysed in detail. Whether you need regular inspections to maintain the integrity of your assets or emergency inspections following a natural disaster, UAS Imagery has the expertise and technology to deliver the results you need